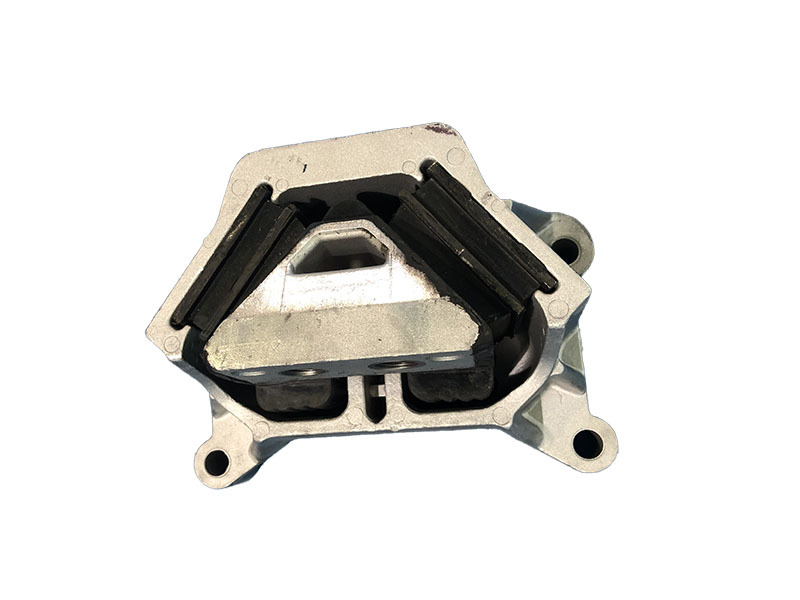

Torque rod bush

Key words:

Category:

Description

Product introduction

The use of 40Cr tempering and quenching center shaft, increase the center ball, high strength is not easy to break, good torque effect, overall improve product life.

Exhibition

FAQ

Torsion rod bushing features

The torsion rod bushing (shock absorbing bushing) is made of polyurethane rubber, which has the characteristics of rigid and flexible. It has a buffering effect on the instantaneous slip friction of the tire, and can effectively eliminate the bias wear and gnawing phenomenon of the trailer tire, so that the tire can achieve uniform wear. In addition, because the suspension is a rigid body, the optimal design of the torsion bar Angle and the shock absorber sleeve (repair sleeve), as well as the accurate adjustment after assembly, can ensure the vertical degree of the axle and the traction pin. To learn more about the characteristics of torque rod bushings, it is recommended to consult a professional for help.

What do you need to pay attention to when using oil seals

Keep clean: When using the oil seal, ensure that the surface and interior of the oil seal are clean and free of impurities and dirt. Impurities and dirt may damage the oil seal, resulting in reduced sealing performance.

Avoid excessive compression or stretching: During the use of the oil seal, avoid excessive compression or stretching. Excessive compression or stretching may cause deformation of the oil seal and affect its sealing performance.

Prevent the oil seal from being exposed to the air for a long time: Prolonged exposure to the air may cause the oil seal to age and affect its service life.

Check the oil seal regularly: check the status of the oil seal regularly. If the oil seal is found to have cracks, aging or other damage, it should be replaced in time.

Pay attention to the installation method: When installing the oil seal, install it in the correct direction and way to ensure that the sealing performance of the oil seal is fully played.

Control oil temperature: In the process of use, to control the temperature of the oil to avoid too high or too low temperature. Too high or too low a temperature may affect the performance and service life of the oil seal.

Avoid unsuitable oil seals: When selecting an oil seal, make sure that the type, size and material of the oil seal are suitable for the specific application. Improper oil seals may result in degraded or damaged seal performance.

How to check whether the oil seal is cracked?

Visual inspection: This is a preliminary inspection method that can check for obvious damage, tearing, aging or cracking by directly observing the appearance of the oil seal.

Leakage test method: The oil seal is installed in a specific test device, and the pressure, temperature, type of lubricating oil and other factors are changed to detect whether the oil seal leaks oil. If the oil seal leaks, it indicates that the seal is not well sealed and needs to be replaced or adjusted.

Torque test method: by setting a torque meter on the journal, and then rotating the journal, by measuring the size of the torque to determine whether the tightness of the oil seal meets the requirements. If the torque is too large or too small, it means that the tightness of the oil seal is not good.

Compressed air method: This is a professional method that requires the use of professional instruments and equipment. By filling the inside of the oil seal with compressed air, observe whether there are bubbles, to judge whether the oil seal has cracks or gas leakage phenomenon.

In general, when conducting oil seal inspection, it is necessary to choose the appropriate method according to the specific situation, and ensure that the test environment is clean and tidy to ensure the accuracy of the test results. If the oil seal is found to have cracks or other problems, it should be replaced in time to ensure the normal operation and safety of the equipment.

Get Quote

NOTE: Please leave your email, our professional person will contact you asap!

Related products